H-2936A

Standard Crack Gauge

Used to monitor horizontal or vertical movement across a crack on a flat surface

HC-2937

Concrete Crack Gauge Plus

Improved design provides easier use and more accurate results

HC-2938

Concrete Crack Gauge for Corners

Hinged mounting allows crack monitoring in corners with 70° to180°angles, sold in pairs

HC-2955

Concrete Crack Data Logger

Crack Detector with Integral Data Logger and USB connectivity

HC-2956

Concrete Crack Data Logger, Wifi

Crack Detector with Integral Data Logger and wireless connectivity

HC-2947

Concrete Crack Monitoring Kit, Essential, Digital

A kit of essential crack monitoring devices featuring digital calipers

HC-2948

Concrete Crack Monitoring Kit, Professional

A complete set of crack monitoring devices featuring Digital Calipers with a data port

HC-2941

Concrete Crack Monitoring Kit

A kit designed to provide all the products needed to set up a crack monitoring program.

HC-2950

Concrete Crack Measuring Microscope

Precision, hand-made product, designed specifically for measuring concrete cracks

HC-2939

Displacement Crack Gauge

Displacement Crack Gauge monitors horizontal and displacement movement

HC-2940

Concrete Crack Width Gauge

Designed to measure widths and locations of cracks prior to crack monitoring program

HC-2942A

Concrete Crack Monitor Adhesive

Very-fast-hardening 2-component Epoxy Adhesive

HC-2944

Concrete Crack Gauge, Screws and Plugs

Suitable for affixing a crack gauge to a flat surface.

HC-2943

Concrete Crack Monitoring Caliper Marks

Plastic caliper marks used to monitor cracks with a caliper, Pkg. of 100

HC-2964

Caliper Marks, Stainless Steel for Crack Monitoring

Stainless steel caliper marks for monitoring cracks with calipers. Pkg. of 100

H-3230.XX

Multi-Length Strain Gauge Set

Designed to measure strain in masonry-type and structural components

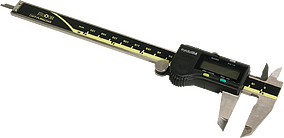

H-2816.XX

Digital Calipers

May be used for outside, inside, depth and step measurements.

Crack Monitors

Cracks in concrete, whether in buildings, roads, structures or bridges, indicate damage and should be closely and accurately monitored to assure the integrity, safety and underlying durability of the structure.

These cracks can form for a number of reasons:

- Sub-par construction practices

- Chemical reactions causing corrosion

- Repeated freezing and thawing

- Construction overloading

- Or any combination of the above.

Depending on where the crack is located, the issue may be superficial or an indication of damage of a larger scale. The significance of the damage depends on the location and size of the crack, and how they can ultimately affect the structure’s safety and durability. Monitoring of the cracks is essential in evaluating what maintenance actions will be needed for the affected area based on the severity of the damage.

A number of different types of evaluations and instruments are available to precisely measure and monitor concrete cracking. These tools are able to continuously monitor and record even subtle opening and closing of the crack.

Humboldt’s concrete crack monitors and crack gauges are of the highest quality available. They feature highly accurate scales and a unique pin system to ensure accurate zeroing of the monitor when it is affixed to the surface. Our crack monitors include use for flat surfaces, corners and displacement applications.

Crack monitor gauges are used to monitor horizontal or vertical crack movement on a flat surface.

Crack monitor gauges for corners allow monitoring in corners with 70° to 180° angles.

The concrete crack data logger monitors cracks and linear displacements, measuring both displacement and ambient temperature with USB connectivity (also available in wireless WiFi).

Concrete crack monitor kits contain the components needed to set up a system using precision digital calipers.

The concrete crack monitoring microscope is a high-definition instrument with its own adjustable light source.

The displacement crack monitoring gauge monitors movement where there is a step across a crack due to displacement.

The concrete crack width gauge measures widths and locations of cracks before staring a monitoring program.

The multi-length strain gauge is recommended as a substitute for the Whittemore strain gauge for masonry-type materials and structural components.

Other related parts and accessories include crack monitor adhesive, screws and plugs, caliper marks and digital calipers.

Humboldt maintains a large inventory for immediate shipment of monitors, whether you need only one or a couple of hundred. If you have questions or need help selecting equipment, please call us at 1.800.544.7220 or use our Ask Humboldt form.